- Artificial Intelligence (AI)

- Occupational exposure limit values

- Climate Change and Occupational Safety

- List of CMR substances

- Electromagnetic fields

- Ergonomics

- Industrial Security

- Collaborative robots

- Noise

- Nanoparticles at the workplace

- Optical Radiation

- REACH

- Reference materials

-

Proficiency testing

- Information for Participants

- Schedule and Fees

- Aldehydes

- Inorganic acids

- Volatile Organic Compounds (VOC)

- Metals on filters

- Organic Solvents

- Polycyclic Aromatic Hydrocarbons (PAHs)

- Test PT diisocyanates on filters

- Test PT direct-reading measuring instruments

- Test gas stream

- Evaluation

- Results 2002 to 2024

- Vibration

- Virtual reality

- Work 4.0

Information for proficiency testing participants for in-house and external measuring stations

Introduction

It is the duty of the company to determine whether a concentration of hazardous substances is in the air at the workplace. The required measurements of the hazardous substances can be conducted by in-house or external measuring stations. A measuring station can be considered to be suitable if it has the necessary expert knowledge and the required facilities. The qualification is assured via an accreditation for measuring stations outside the company [1].

No formal accreditation is provided for in-house measuring stations (IMS). Nevertheless, the in-house measuring stations also must fulfil the requirements for measuring stations according to TRGS 402 (Technical Regulation for Hazardous Substances) [2]. To maintain the quality parameters for analytic procedures, the quality assurance methods are to be used that are state-of-the-art. The Institute for Occupational Safety and Health of the German Social Accident Insurance (IFA) provides proficiency testing as support and assistance for the measuring stations [3]. This should give them an opportunity to examine and document their own quality through external quality assurance procedures.

All proficiency testing schemes are being conducted in compliance with DIN ISO 13528 and with DIN ISO/IEC 17043 [4, 5].

Organisation/carrying out of the proficiency testing schemes

Organisation and performance of the PT schemes, including evaluation and documentation of the results, are conducted by the IFA. The PT schemes offered are intended to cover the widest possible range of hazardous substances. The PT schemes are offered either with own sampling or without own sampling, with the exception of the PT scheme metals and diisocyanates (only without own sampling). This means that the participants receive ready-loaded samples, or they load their sample carriers themselves at the dynamic test gas stream of the IFA. Furthermore, participation in the test PT scheme for direct-reading measuring instruments is only possible on site.

According to DIN EN 482 the minimum measuring range for a workplace air measurement method has to cover a range normally from 0.1 times to 2 times the occupational exposure limit value [6, 7]. The adjusted concentration range in the PT schemes corresponds to this requirement. Information on the occupational exposure limit values is given in the database "GESTIS - International limit values" [8].

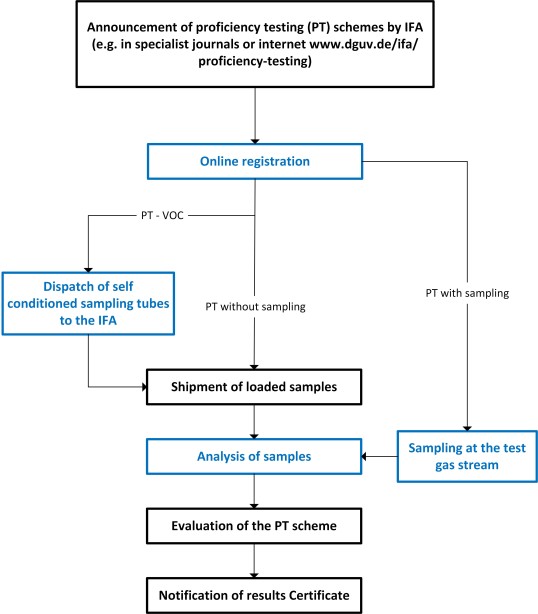

The different PT schemes are conducted regularly, usually once a year on different dates. The dates are announced at the end of each year for the following year on this website. The procedure for the PT schemes is always similar (see flow chart).

The production of the samples is done either at the IFA, or at the Institute for the Research of Hazardous Substances (IGF) of the German Social Accident Insurance Institution for the raw materials and chemical industry (BG RCI) in Dortmund.

The registration for the PT schemes is done online by the participants via the online portal for the PT schemes of the IFA. This platform offers the following possibilities in the participation area:

- Registration for the PT schemes

- Entering of measurement data / results

- Download of Individual evaluation reports and certificates

- Management of the user account (self-updating password, e-mail, etc.)

- Management of the laboratory details (address data, laboratory-specific users, ...)

There is a limited number of sample ports to load the sample tubes. Upon reaching the maximum number of participants we reserve the right to terminate the registration prematurely. On request you can be put on the waiting list if a PT is fully booked. Please consider the registration deadlines indicated on the online platform.

Processing and documenting the analytic results

When the samples are delivered, the processing period is stated, which is usually about four weeks. After the analysis and evaluation, the results are entered directly by the participants in the online portal. The input mask there contains all the necessary information for the data entry.

In addition, questions about the general conditions of sampling, if applicable, and the analysis and evaluation should be answered. Nevertheless, answering the questions is voluntary. The participants receive an overview with the anonymised answers of all participants in the proficiency testing evaluation.

Sources

[1] Gesetz über die Durchführung von Maßnahmen des Arbeitsschutzes zur Verbesserung der Sicherheit und des Gesundheitsschutzes der Beschäftigten bei der Arbeit (Arbeitsschutzgesetz – ArbSchG) vom 7. August 1996 (BGBl. I, S. 1246). Zuletzt geändert am 5. Februar 2009 (BGBl. I, S. 160)

[2] TRGS 402: Ermitteln und Beurteilen der Gefährdungen bei Tätigkeiten mit Gefahrstoffen: Inhalative Exposition (09.2023)

[3] Qualitätssicherung durch Ringversuche an der dynamischen Prüfgasstrecke des IFA (Kennzahl 1630) In: IFA-Arbeitsmappe Messung von Gefahrstoffen. Lieferung 01/2021

[4] ISO 13528: Statistical methods for use in proficiency testing by interlaboratory comparison (08.2022). International Organization for Standardization, 2022

[5] ISO/IEC 17043: Conformity assessment — General requirements for proficiency testing (10.2023). International Organization for Standardization, 2023

[6] EN 482: Workplace exposure - Procedures for the determination of the concentration of chemical agents - Basic performance requirements. 2021

[7] ISO 20581: Workplace air – General requirements for the performance of procedures for the measurement of chemical agents. International Organization for Standardization, 2016

[8] GESTIS - International limit values for chemical agents (Occupational exposure limits, OELs)