- Artificial Intelligence (AI)

- Occupational exposure limit values

- Climate Change and Occupational Safety

- List of CMR substances

- Electromagnetic fields

- Ergonomics

- Industrial Security

- Collaborative robots

- Noise

- Nanoparticles at the workplace

- Optische Strahlung

- REACH

- Reference materials

- Proficiency testing

- Vibration

- Virtual reality

- Work 4.0

Applications of virtual reality

In SUTAVE Laboratory, new and cutting-edge technology is used to meet the challenges presented by occupational safety and health (OSH). OSH is a field in which virtual reality (VR) has a wide range of uses. VR is:

- A simulation technology with which existing and future workplaces and technologies can be demonstrated and trialled

- A method with which work equipment can be developed, analysed, evaluated and improved at workplaces

- A new technology with which preventive activity in occupational safety and health and health protection can be prepared for the future

The use of VR for simulation purposes takes work processes in human-system interaction out of the shop floor and into the laboratory, from the design phase through to disposal. VR is used in concept studies for new protective devices or for the upgrading of products during their life-cycle. The results of risk and hazard assessments serve as the terms of reference for design; products are then analysed, assessed with reference to principles, if necessary redesigned, and finally evaluated.

Products in work systems are simulated in virtual reality in order for them to be adapted to the requirements imposed upon the processes of information processing by human beings. The following products are particularly important for sustainable prevention work:

- even where they do not yet exist in reality. This enables errors in development to be avoided (for example by the development of effective safety concepts for new machines or installations).

- when they are to be avoided, because they would constitute a hazard (as in the case of protective devices not or no more appropriate to safeguard machinery or equipment).

- when study of them would be too expensive (for example owing to the down times of machines and personnel when studies are performed in situ).

- when they no longer work in their original state because they have been damaged (for example in the context of accident investigations or fault analyses).

- when they cannot be studied empirically with systematic variation of standardized conditions, because the conditions are not repeatable (for example validation studies for product design).

- when testing is difficult, because their quality is subject to rapid change (for example under heavy wear or degradation).

The principles of safe, usable and ergonomic design can be analysed, developed and evaluated by the method of VR. VR can be used to assess the suitability of existing principles for application to the products' design. Studies are performed in the SUTAVE laboratory in order to identify new design requirements for the interaction between the human being and the work system, and if necessary for areas of application and the conditions of a work system to be specified. These studies are supported by analysis methods adapted to VR and suitable for combination with measures for enhanced evaluation of risk, hazard and usability.

VR is a technology that is increasingly being used within industry and services and in all phases of product development. Design recommendations can be considered during consultations between the social accident insurance institutions and their insured companies for the introduction of new technology in human-system interaction. At the same time, the scope and limits of VR for occupational safety and health can be defined more closely.

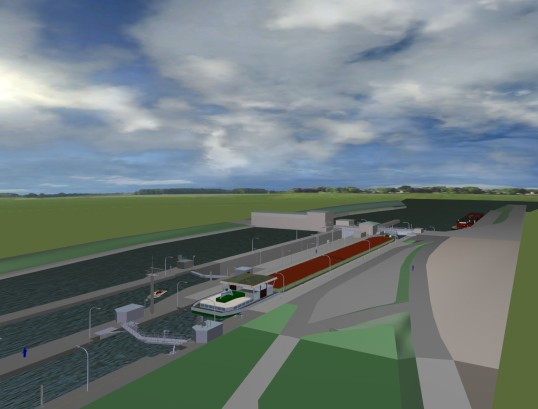

Equipment of the IFA's SUTAVE laboratory