- Artificial Intelligence (AI)

- Occupational exposure limit values

- Climate Change and Occupational Safety

- List of CMR substances

- Ergonomics

- EU GHS Regulation

- Industrial Security

- Collaborative robots

- Noise

- Nanoparticles at the workplace

- REACH

- Reference materials

- Proficiency testing

- Radiation

- Vibration

- Virtual reality

- Work 4.0

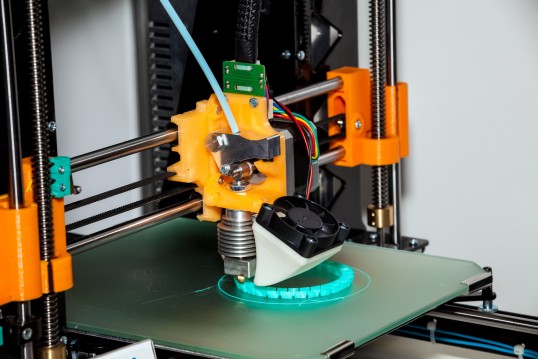

3D printers

3D printers are becoming more and more common. Current spheres of OSH research aim to deliver valid conclusions regarding emissions from 3D printers and therefore their possible impacts upon the health of workers.

For some years, additive manufacturing (AM) has been the subject of considerable hype in the media under the buzzwords of 3D printers or rapid prototyping and manufacturing. Production techniques such as selective laser sintering have however existed for some 20 years. At present they are used primarily for the production of prototypes and for short production runs.

Additive manufacturing methods include any method in which a substance is built up in layers in order to produce a part. Based upon data models, these parts are produced by means of chemical and/or physical processes from liquids, powders, or material in strip or wire form.

Increasing numbers of manufacturing companies are offering the service of printing out components directly. Customers need only upload the relevant CAD files to the service company; the latter's programs enable the desired part, made from the appropriate material, to be ordered online at the click of a mouse. Once printed out, the part is shipped.

Additive manufacturing is also increasingly being adopted by other users, however: owing to the dramatic drop in prices, more and more installations are appearing on the market and are being used in educational establishments such as universities and their institutes, in industrial R&D departments, and in small and medium-sized enterprises such as engineering offices and dental laboratories.

Additive manufacturing methods are now to enable rapid prototyping/manufacturing to be scaled to high-volume series production. They are used in all areas where batch sizes of one are required, whether in prosthetics, rare spare parts or aerospace.

Despite the growing spread of 3D printing, at present (2019) hardly any valid German studies have delivered conclusions regarding possible hazards to the health of workers during the use of additive manufacturing methods. The IFA intends to rectify this deficit by means of its research activities on the topic of 3D printers.

In addition, the unit responsible for the Measurement system for exposure assessment of the German Social Accident Insurance Institutions (MGU) has set up a measurement campaign in the area of exposure associated with additive manufacturing methods, including 3D printers. Particular attention will be paid to the materials employed, such as metals, acrylonitrile butadiene styrene (ABS) and polylactic acid (PLA). Of particular interest are for example powder(bed)-based methods, stereolithography and fused layer modelling (FLM). For this purpose, the inhalative exposure to hazardous substances was measured in production areas and at office-type workplaces. Examples of the substances include:

- Volatile organic compounds (VOCs)

- Aldehydes

- Ultrafine particles

- Carcinogenic, mutagenic and reprotoxic (CMR) substances

- Respirable and inhalable dusts

In 2018, measurements were carried out on 3D printer desktop devices. The results show that the measured concentrations of emissions released during printing are well below the occupational exposure limits.

Exposure descriptions and other publications will be published in the course of 2020. In a second step, Recommendations for Hazard Identification of the Accident Insurers (EGUs) are planned for selected techniques.

Further Information

Beisser, R. et al.: Inhalation exposure to metals during additive processes (3D printing) (PDF, 776 kB, non-accessible)

Translated from: Gefahrstoffe - Reinhaltung der Luft 77 (2017) No. 11/12, p. 487-496

Contact

Hazardous substances: handling, protective measures

Tel: +49 30 13001-3310Fax: +49 30 13001-38001